Excellent Solution

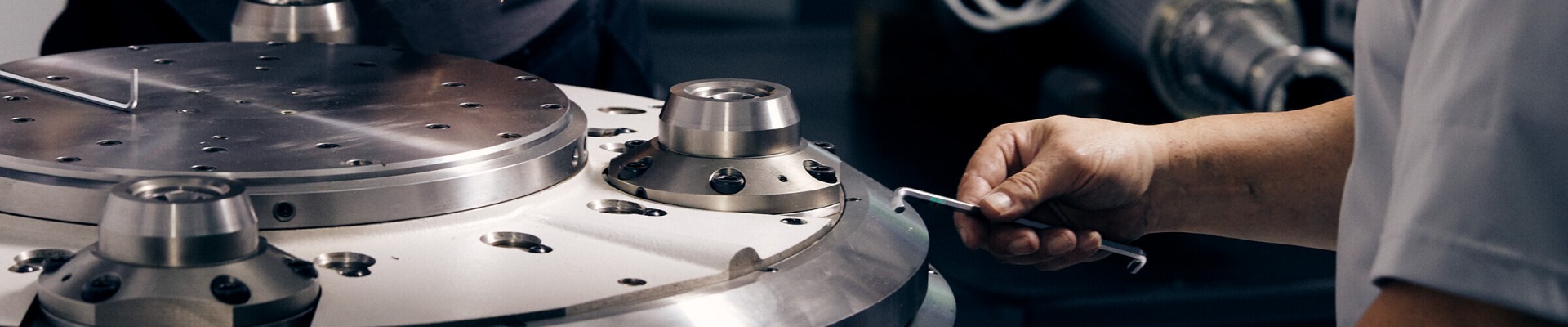

Hyluo provides high-quality CNC machining services with tight tolerances. We have a vast range of capabilities, ranging from general-purpose machining to precision CNC machining of critical, high-value parts for demanding industries. Our global network of manufacturing partners works with an extensive range of materials and adheres to the highest quality standards. We manage the entire project, from PO to delivery, and our company, as well as all the machine shops we work with, hold the most current ISO 9001 and IATF 16949 certifications to ensure exceptional quality.

Our expertise and focus on quality control ensures dependable, accurate parts for a wide range of applications. including: Aerospace, Medical, Oil and gas, Automotive, Electronics and Commercial etc. and have been highly praised by customers.

Our continuing commitment to quality, delivery reliability, innovation and ingenuity has won the respect and appreciation of hundreds of our customers. We invite you to contact our engineers and let them help with your current manufacturing needs.

4 points show that Hyluo machining deserves your faith

1. Specialization

The manufacture and assembly of custom machined parts is our only business and is one that we are absolutely committed to doing well, consistently for all of our customers. We never "take our eye off the ball" when it comes to listening to our customer and making absolutely sure that we are giving them 100% service and attention to their needs.

2. Versatility

At Hyluo, we utilize CNC 3, 4, & 5 axis mills, CNC mill-turn centers and state-of-art multi-axis CNC turning equipments so that we can guarantee our customers that they are getting the best parts for their money, made using the most efficient process.

We also have specialty CNC machining capabilities for surface, cylindrical, and profile grinding, gear hobbing, spline cutting, thread rolling, and EDM. With the range of available equipment and 3D modeling and CAM capabilities, we can handle the machining requirements for virtually any project, no matter how intricate or complex.

We machine parts using a wide range of bar stock, from soft metals like aluminum and brass to the hardest titanium and cobalt-chrome alloys. In addition, we machine castings, forgings, rigid engineering plastics, and graphite. Our inspection methods include CMM, contour profiling, video measurement, NDT, gauging, and scanning.

As a full-service source for machined components, we carry out necessary secondary operations such as heat treatment, surface treatment, etc. We also offer product assembly and integration. With our managed inventory programs, we ensure parts are in stock for just-in-time delivery.

3. Dedication

- Highly Efficient Energy Transfer

We take great pride in doing our personal best for all of our customers. From a careful process and tooling review of your part, through set up and first article inspection, all the way to making every shipment, we want to be sure that your parts are made the way you want them and shipped to you when you need them, every time! At Hyluo, we feel that every order, regardless of size, deserves our maximum attention and effort. Our many, happy and satisfied customers will readily attest to this statement.

4. Quality Policy

Hyluo is committed to the continuous improvement of its Quality Management System and to complete customer satisfaction, as specifically defined by achieving:

Product that is manufactured securely within the customer's specified tolerances.

Product that is manufactured securely within the customer's specified tolerances.

Deliveries that meet or exceed the customer's expectations.

Deliveries that meet or exceed the customer's expectations.

Personal attention to all communications with the customer.

Personal attention to all communications with the customer.

Our dedication to the highest quality and on-time delivery serves many industries with critical CNC machining service needs.Through technological innovation, there is a higher guarantee in safety, economic efficiency and service life, and it also brings higher value returns to customers.